Welcome to the first edition of the DriftBastards BUILD BLOG for the RB S13.

You know, we place great value on the appearance of our cars. However, we are sure that many of you are burning with curiosity about what’s under the pretty hoods. Well, you’re in the right place! In our BLOG for all the tech nerds, we take you behind the scenes.

Over the past few years, we’ve worked on a new car, sometimes more, sometimes less, and documented the entire process as best as we could. Almost all of the work was done by Janick with support from friends and sponsors. Throughout the blogs (yes, more are coming), you’ll see that this is only possible with a lot of support. We hope you enjoy reading!

Why we needed a new car?

Even before the Drift Bastards were founded, Domenik Sieber owned an S13, which was modified for professional drifting.

A simple bolt-in roll cage from Cusco, a 500hp RB25 engine, a suspension made from various used aftermarket parts, and a conventional fuel cell were the state of the art at the time.

However, motorsport is a very dynamic thing. Not only do the cars move at incredible speeds, but regulations and guidelines from organizers, as well as technological innovations and newly available performance parts, continuously evolve the scene.

As a result, the red S13 quickly became non-compliant with the regulations of competition events after only a few appearances and a short period of time.

Anyone who follows the drift scene will realize that we are no exception. In the higher leagues, engine outputs of up to 1000 horsepower are no longer uncommon. The grip levels of tires and suspension are now so high that a well-tuned drifter can easily keep up with a race car. Super-soft 285 semi-slick tires and just enough tire pressure to keep them on the rims make today’s drift cars true traction monsters. It’s not just smoke, but also the forward drive that makes the sport increasingly spectacular."

Domenik and Janick quickly realized that the red Nissan wouldn't be able to keep up for much longer. Before they lost interest in competition events, they began planning for the future behind the scenes.

No, the new car is not intended to be a pure competition drift car, but it should still comply with all regulations in case the motivation for a competition event or championship arises.

Drift Challenge, "TUNER GP" Hockenheimring 2018

Domenik’s S13 always stood out with its unique style, and the RB engine provided the perfect sound backdrop!

But now it’s time to radically modernize the car.

After this brief introduction, you now know what’s going on.

S13 Version 2.0

The red Nissan, which mostly worked very well and reliably, continued to be driven for the time being. Meanwhile, something new could be built without sacrificing driving time. At the end of autumn 2018, a new S-chassis was acquired from friendly drifter Ronny Hunziker.

It's funny when I think about how we paid a case of beer for a 180SX Type-X that was imported from Japan back then. Today, that would be unthinkable for these cars.

The RHD S-chassis was in an advanced stage of being stripped down, missing the SR20 engine, transmission, bumpers, and all interior parts.

Still, a very fair price. Simply ideal as a base for our new drift car.

Danke Ronny 😉

Once all the remaining components were removed, it was straight to the metal. The bare body shell was taken to a company in the neighboring village, where it was thermally stripped of all paint, sealant, filler, and soundproofing mats. Thermal stripping is, compared to an acid bath, a cost-effective alternative.

Working on the bare metal is great. Unnecessary body parts that were no longer needed were removed right away.

To protect the bare metal from rust, a rustproofing treatment was applied.

Some nasty rust spots that had formed on both side sills had to be repaired first in order to create a solid foundation.

A solid foundation! This should not be underestimated, and it’s also the key to the next step in the process.

We quickly built a body jig from 100x100mm square steel tubing. Each corner has an adjustable support foot with a 30mm thread, so the entire car can be leveled. Four wheels provide the necessary mobility in case space needs to be cleared in the workshop.

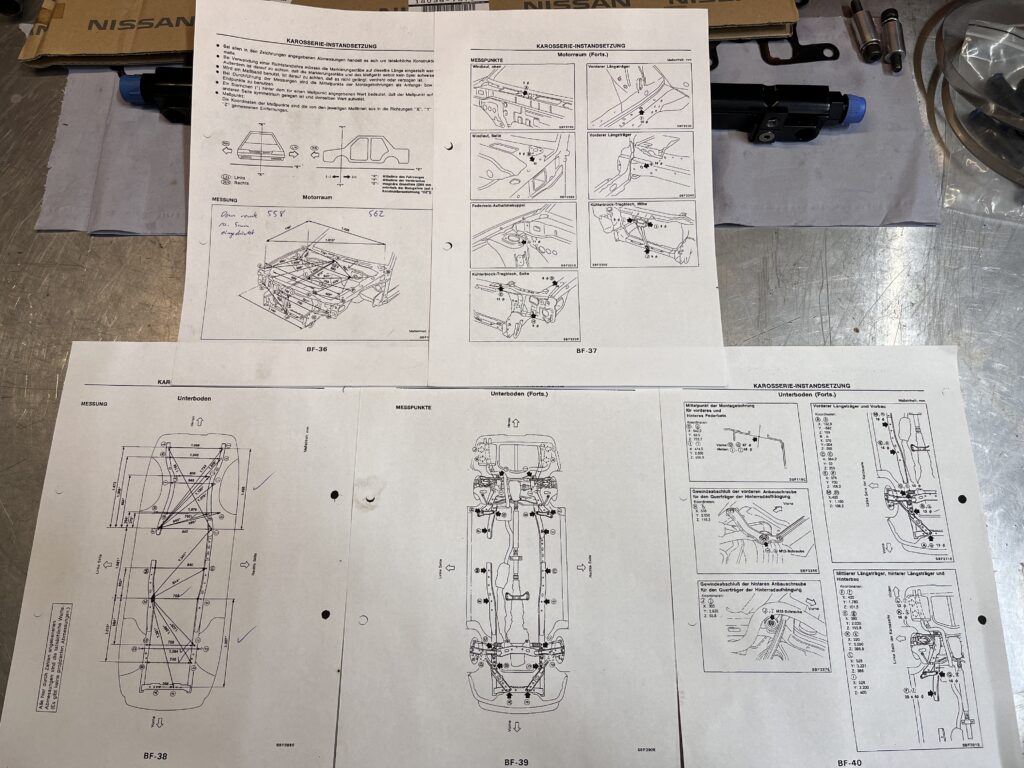

The additional frame proved to be extremely useful for checking the body for damage and distortion. The original workshop manuals from Nissan list all the essential measurements. The car was aligned to 0° with the level feet, and after an hour of measuring, it was clear that this would make a great drift car. Once it was confirmed that no junk had been purchased, work could begin.

All the sheet metal connections on the body were additionally spot-welded. This is a common method in motorsport to reinforce the body and increase its rigidity.

With three to four times the original engine power, this is necessary to keep metal movement to a minimum.

Thermal stripping is just an awesome process.

The chassis frame on the driver’s side is divided in all S13 chassis. No one really knows what the Nissan engineers were thinking with that design. For this reason, we connected and reinforced the rear and front frame halves with a sheet metal plate.

In the new car, we also decided on a Nissan inline 6-cylinder. The RB25DET from the Skyline has served us well so far. We know the RB engine inside and out. To understand what needs to be done to make it durable and powerful enough for a full drifting season, we've already paid our dues and are sticking with this vehicle-engine combination. It’s just very sexy to have an RB in an SX.

In the next blog issue, we will weld in a roll cage and create enough space for a very special transmission.

We’ve opened the comment section further down for any questions or suggestions. Feel free to leave a comment!

What an amzazing build!

needs to be back on track...

Cant wait to see/hear that RB making some HEAT

Thanks Rafale, we will try to finish and test the car this year