We have now reached the third edition of the Build Blogs.

In this edition, you can expect a new garage, new friends, and a bunch of horsepower. We hope you enjoy reading it.

After finishing the roll cage and transmission tunnel in the last blog, we went straight into the 2020 drift season.

The coronavirus gave us a hard time at the beginning of the year, and almost all racing events were suddenly put on hold. As if that wasn’t stressful enough, we also had the lease on our beloved garage terminated. This meant Domenik and Janick had to embark on a tedious search for a new home.

It took almost half a year until Domenik got a chance, which he accepted without hesitation. By chance, they learned that a factory building nearby had become available. The landlord had actually already promised the 150 square meters to a friend, but over a beer after work, they were able to convince him.

The move was now on. The old garage had to be cleared immediately. Together with the new co-tenants, everything was dismantled and rebuilt in the new hall.

Then the start was in January 2021.

Dismantling the old location…

Setup at the new location, February…

The second floor absolutely had to come along, as there wouldn’t have been enough space otherwise in the new hall. After four truckloads, the setup began!

Sorry that we can’t show more photos. During the move, we had our hands full, and over the years, unfortunately, many pictures got lost. But we think you can clearly see the effort we put in to create a new drift headquarters.

To still give you something to look at, here are some pictures of how the garage looks today as a finished mechanic’s dream.

Most of you have probably noticed that not only drift cars are in the garage, but there’s also a slingshot dragster hanging from the ceiling and another quarter-mile beast being built underneath.

Our newly gained friends have dedicated themselves to the drag strip and have been running their US dragsters in Europe for years. The mix between drag racing and drifting fits perfectly, and both teams complement each other well.

Definitely a win-win situation, if you ask us.

We might do a blog about the 'DragBastards' in the future. So stay tuned!

In the new garage, there’s room for everything a mechanic’s heart desires: two lifts, a tire machine, workbenches, shelves, and cabinets for storing all kinds of workshop gear.

Underneath the second floor, our S13 project has found a new home. The space is now used as a metal workshop—drill press, welding table, welding machine, and belt sanders included. New equipment is constantly being added. Janick is always on the lookout for new tools or expansions to the machine park.

We don’t want to spoil too much. The new car is meant to be a surprise, so here it is pixelated!

After almost a year-long moving break and ongoing drift events, work on the S13 can finally continue in the new workshop.

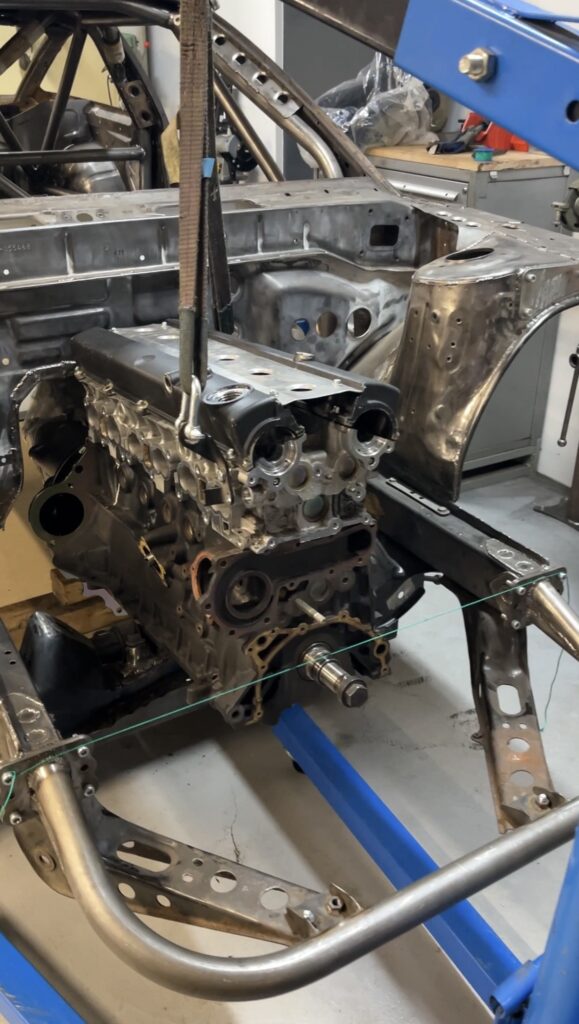

The next big project was the drivetrain. It had to be done as meticulously as possible. An engine that sits crooked or isn’t properly aligned with the body or rear axle can cause major problems later on. Once the engine and transmission are in place, all other parts will be mounted around them.

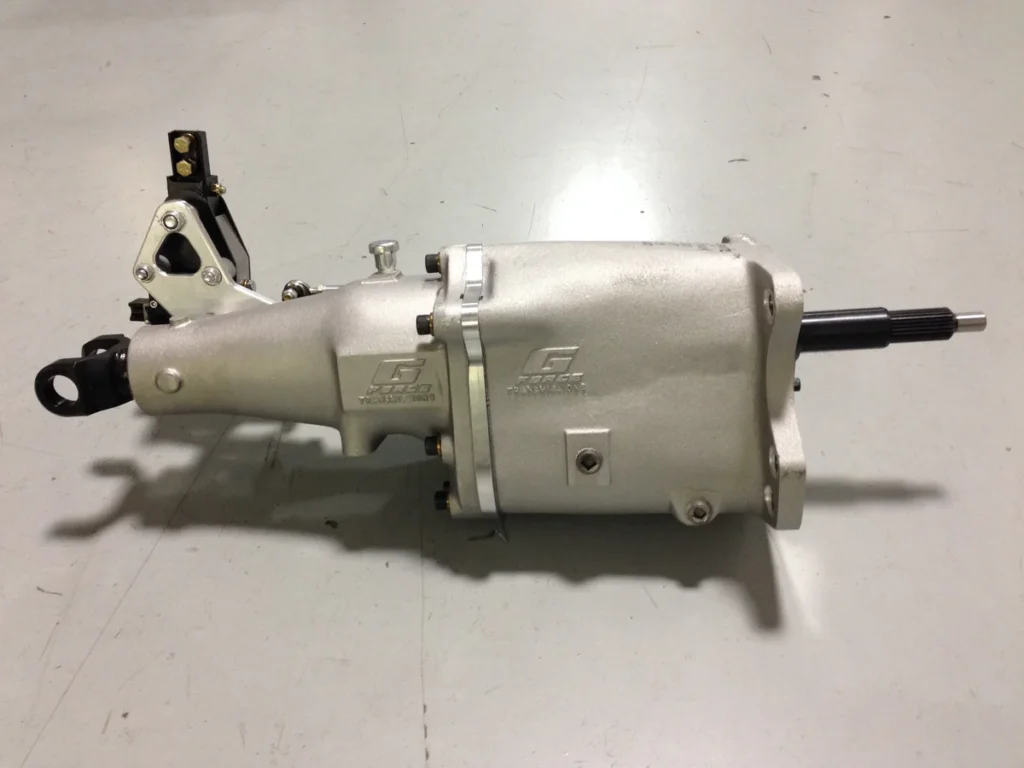

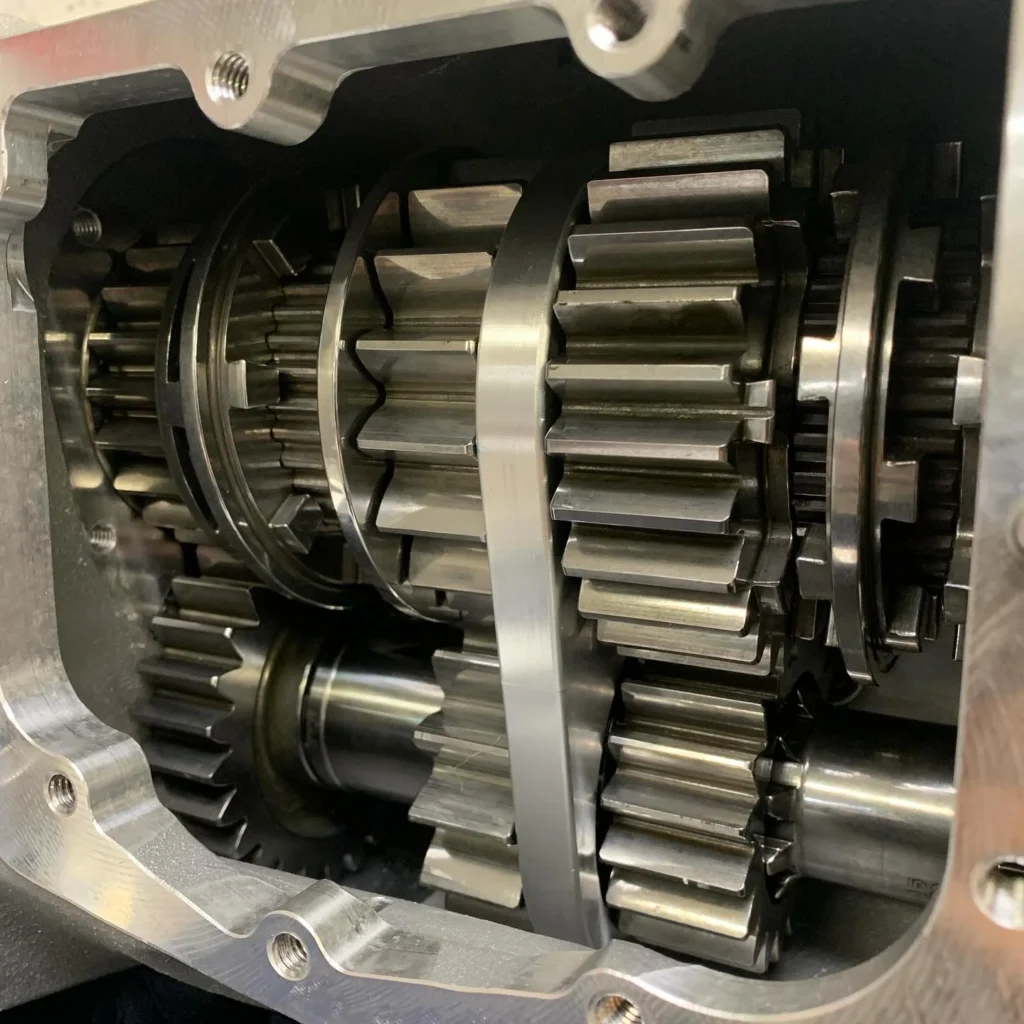

Our choice for a real race transmission fell on the GForce 101a Dogbox. This gearbox was developed for the NASCAR series in America and is based on the 4-speed side-shifter found in some muscle cars. Thanks to its extremely robust design, it remains one of the most popular alternatives to expensive sequential gearboxes even after decades. The price-performance ratio is hard to beat, and the gear ratios are fully customizable. Our Alexander already runs the GForce in his S14 and is very happy with it. During the move, Domenik ordered the exact same gearbox from the USA, which was delivered a few weeks later.

We mounted the GForce with a QuickTime bellhousing onto an old RB25 engine block and got straight to installing it. An engine hoist was used to lift everything into the engine bay.

The RB25/26 engine is tilted 10° toward the exhaust side. This is due to the tall design of the inline six-cylinder. Nissan’s engineers did this to keep the center of gravity as low as possible and to ensure everything fits under the hood. We naturally followed that approach and didn’t want to reinvent the wheel. Using an angle gauge, laser, and string, everything was aligned first. Then came the engine mounts and a transmission support.

The side-shifter turned out to be a real challenge. The shift linkage is offset toward the driver’s side, and enough space for removal had to be taken into account. As a result, the transmission tunnel had to be modified again.

Der Motor wurde zur besseren Wartungsfreundliche direkt an die Längsträger der Karosserie geschweißt. Im Notfall muss das Auto in kürzester Zeit repariert werden können. Dank dieser Bauweise können wir in Zukunft die komplette Vorderachse demontieren ohne den Motor abstützen zu müssen.

Once the engine and transmission were installed, we could tackle the driver’s position, as well as the steering column and pedals.

We chose a Woodward steering column and a hanging Tilton pedal set. These parts are used worldwide in race cars and are of the highest quality. Since the driver’s position is just as important as a perfect drivetrain, we took a bit more time here to make it as comfortable as possible for Domenik.

In the driver’s footwell, a 2 mm aluminum floor panel was installed. Janick designed the panel himself and had it laser-cut externally. To spruce it up a bit, the aluminum sheet was treated with dimple dies. Cleco pins were used for precise alignment.

We’re already coming to the end of this build blog. As always, we hope you enjoyed the detailed behind-the-scenes look.

Be sure to join us next time when we continue with the RB S13!